Solutions

-

+

Commercial Water Softeners

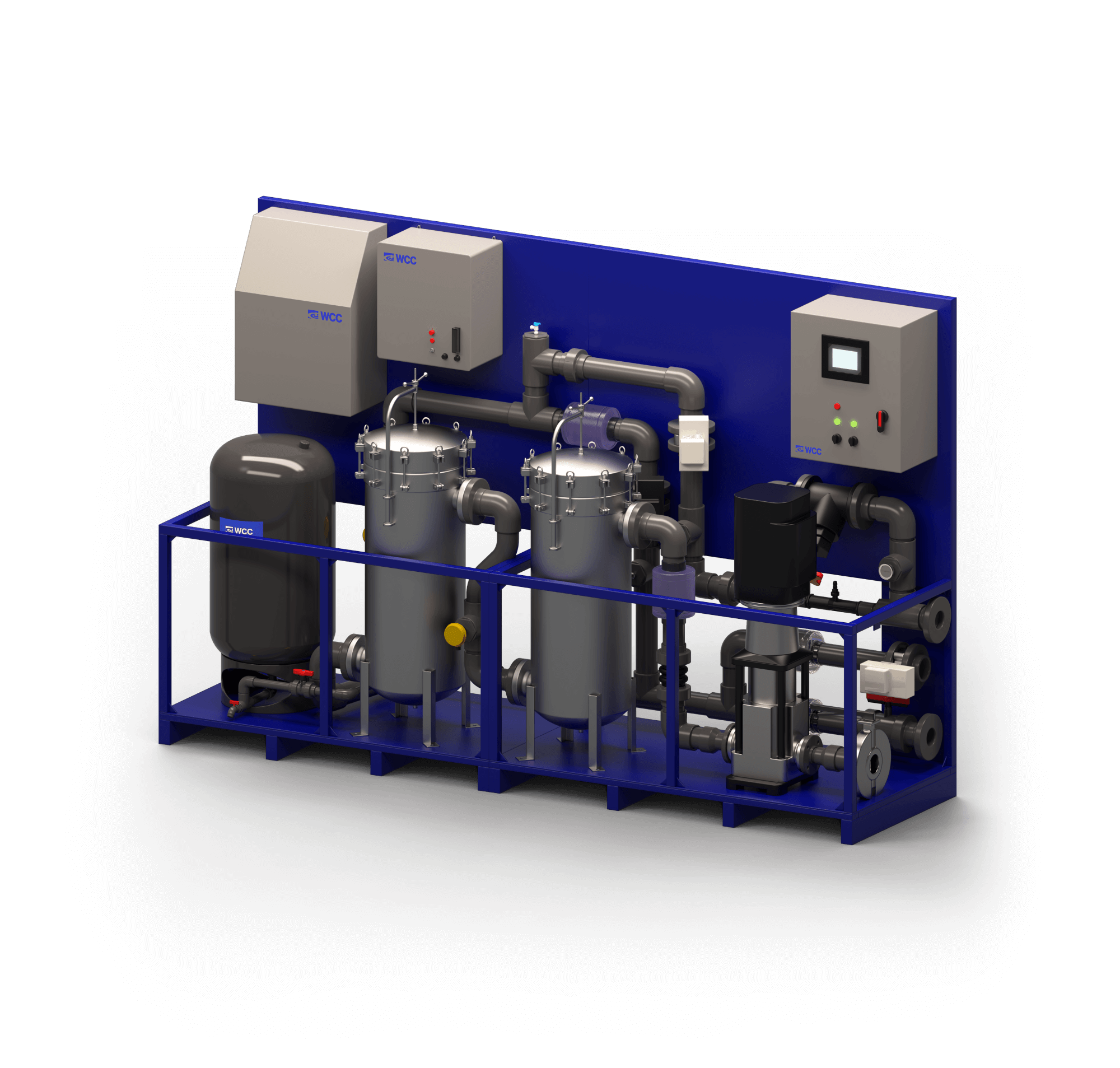

Legionella and Pathogen Control

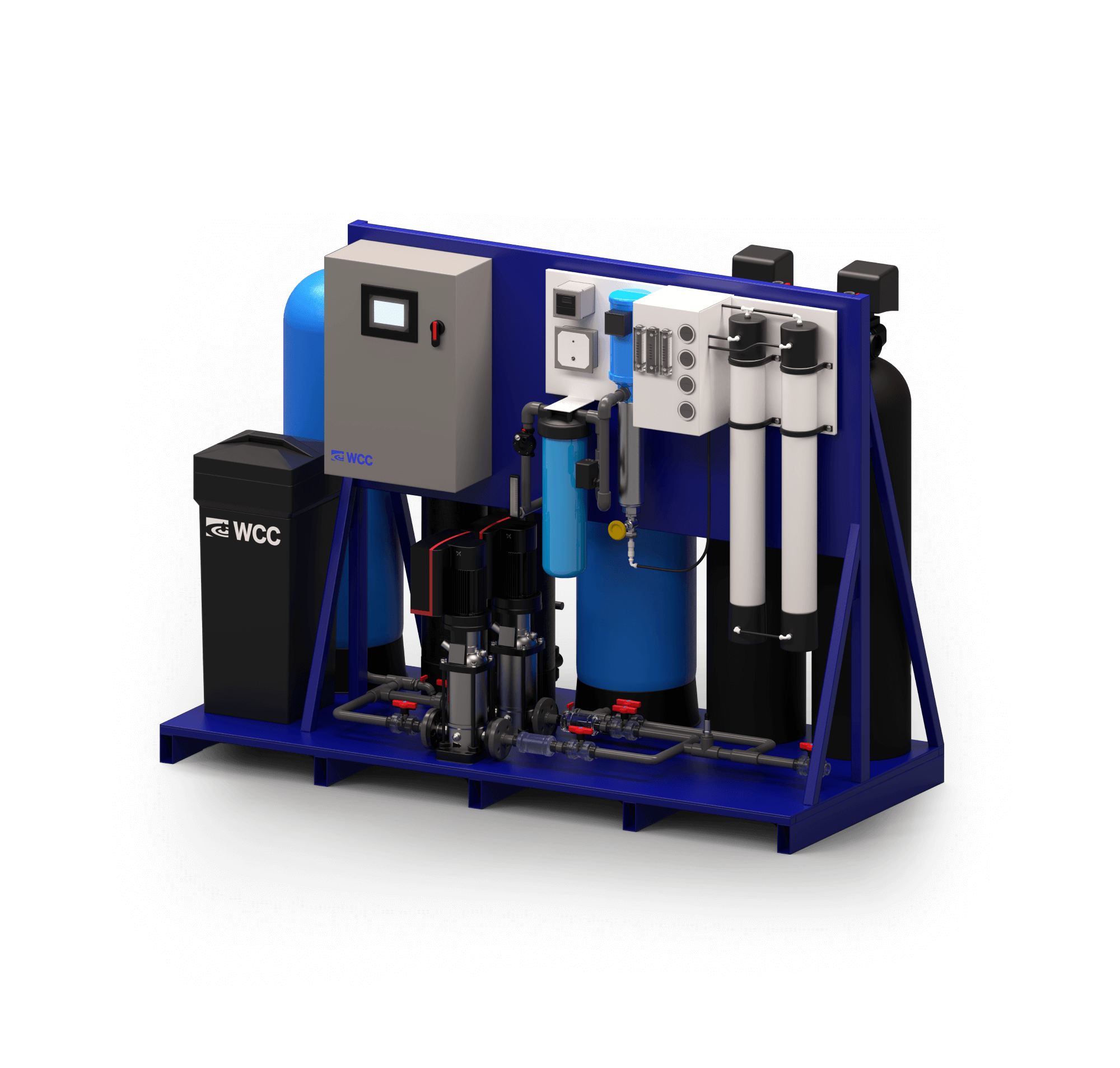

High-Purity Water Systems

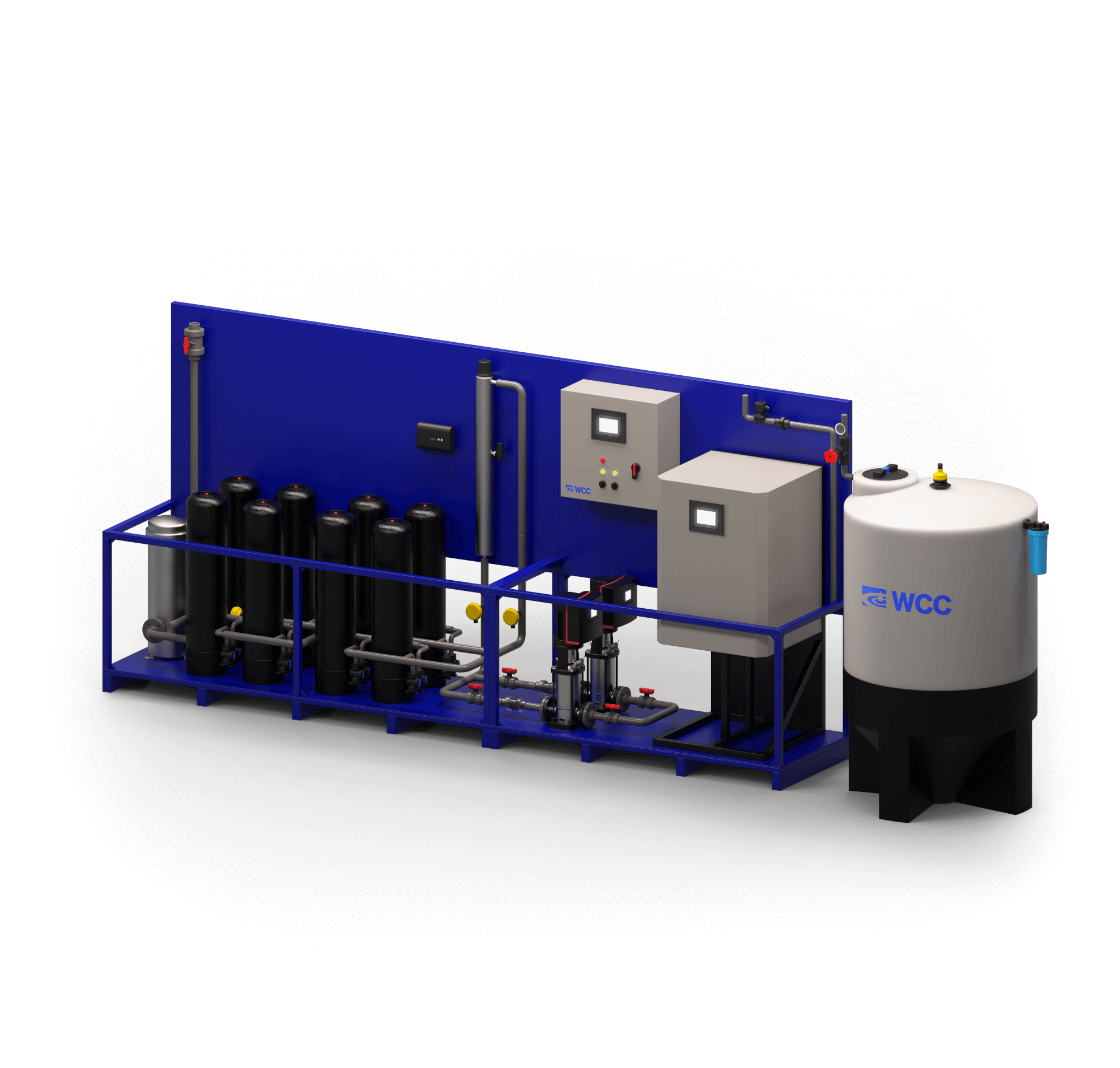

Commercial Water Reclaim Systems

Water Treatment for Commercial Humidification

Specialty Filtration Systems

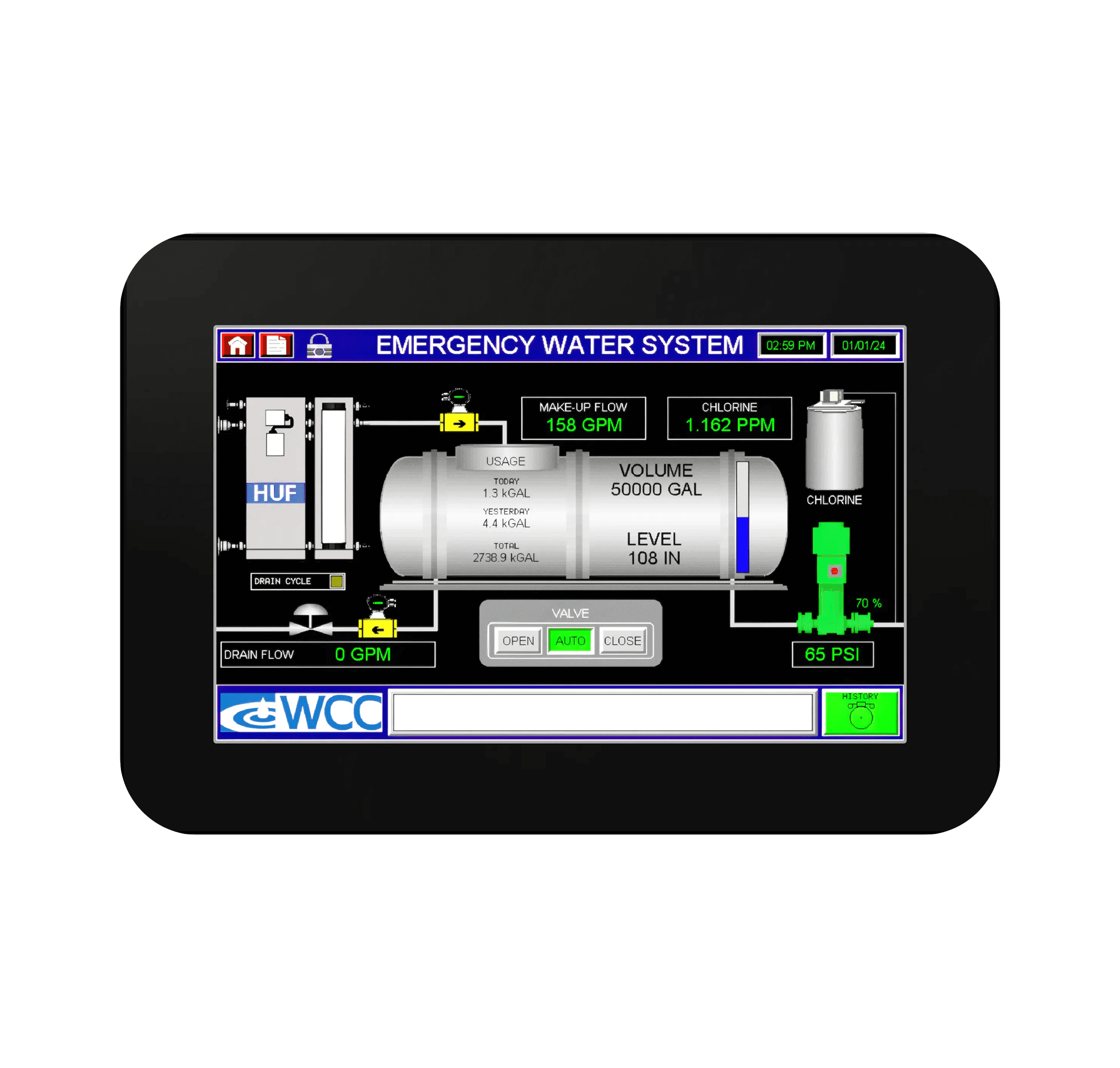

Emergency Backup Water Systems

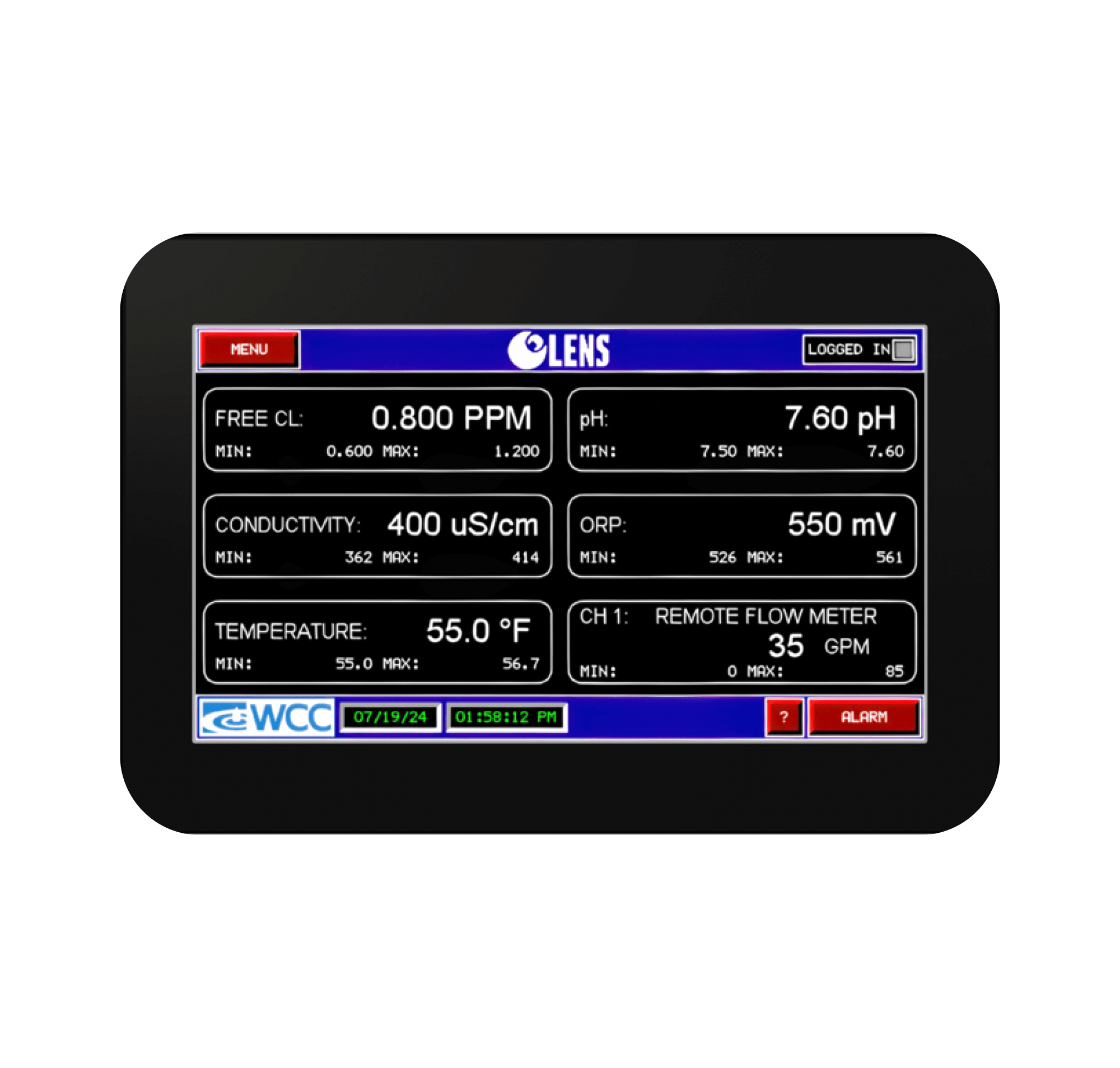

LENS™ Water Quality Monitoring Systems

Lab-Grade Water Purification

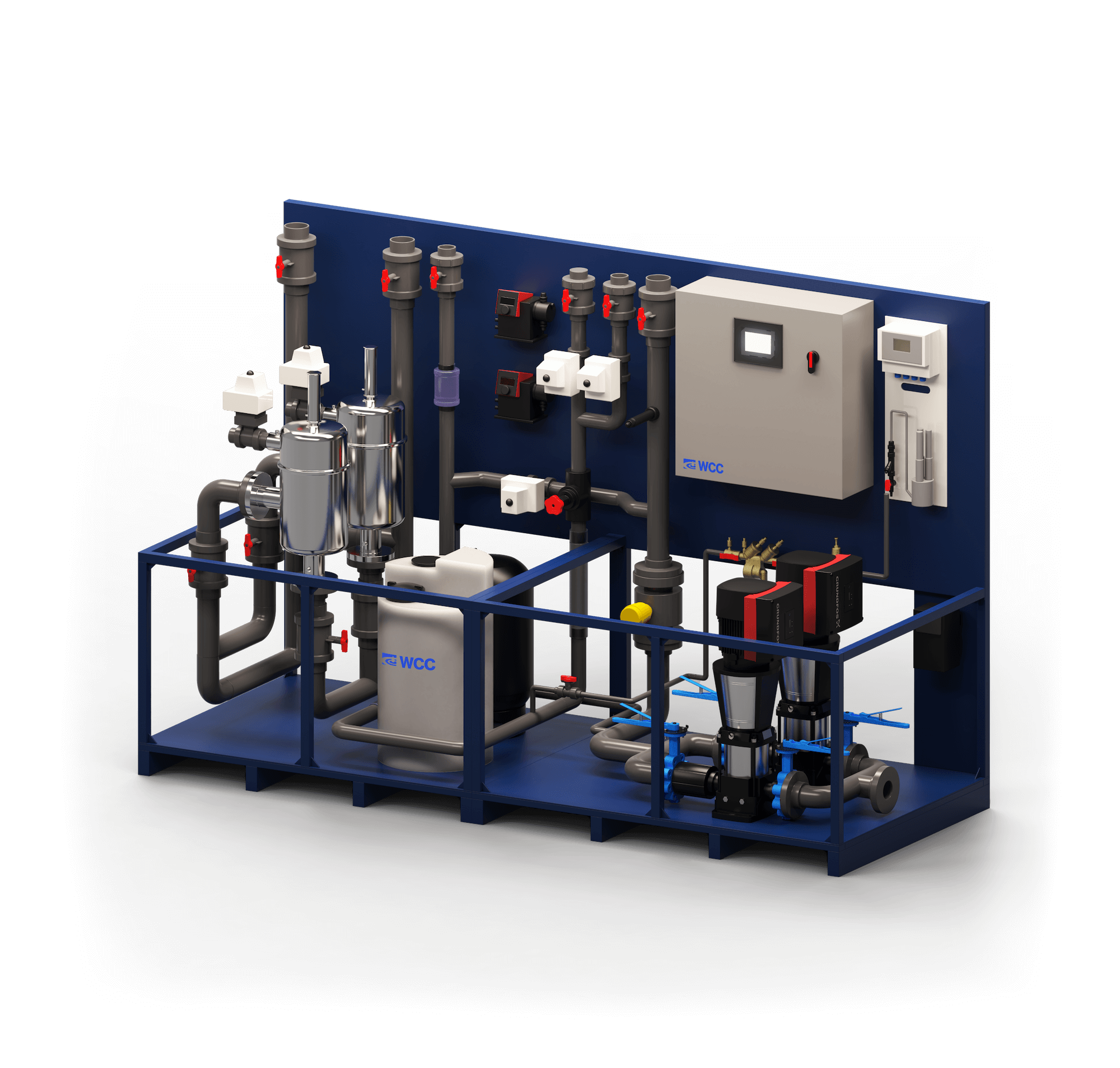

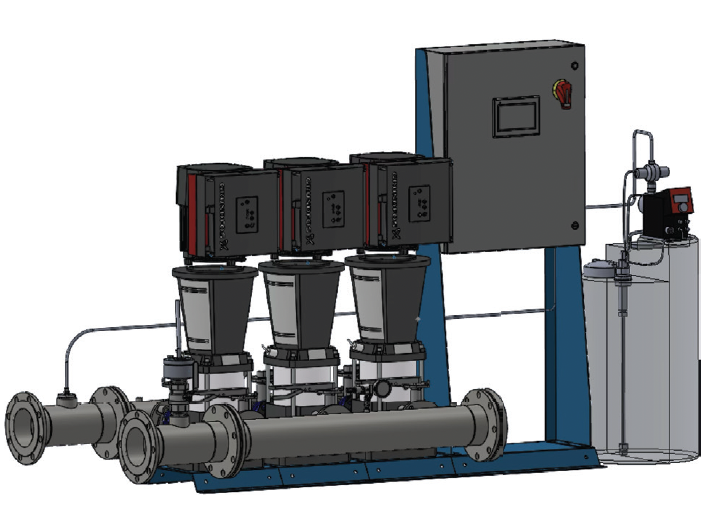

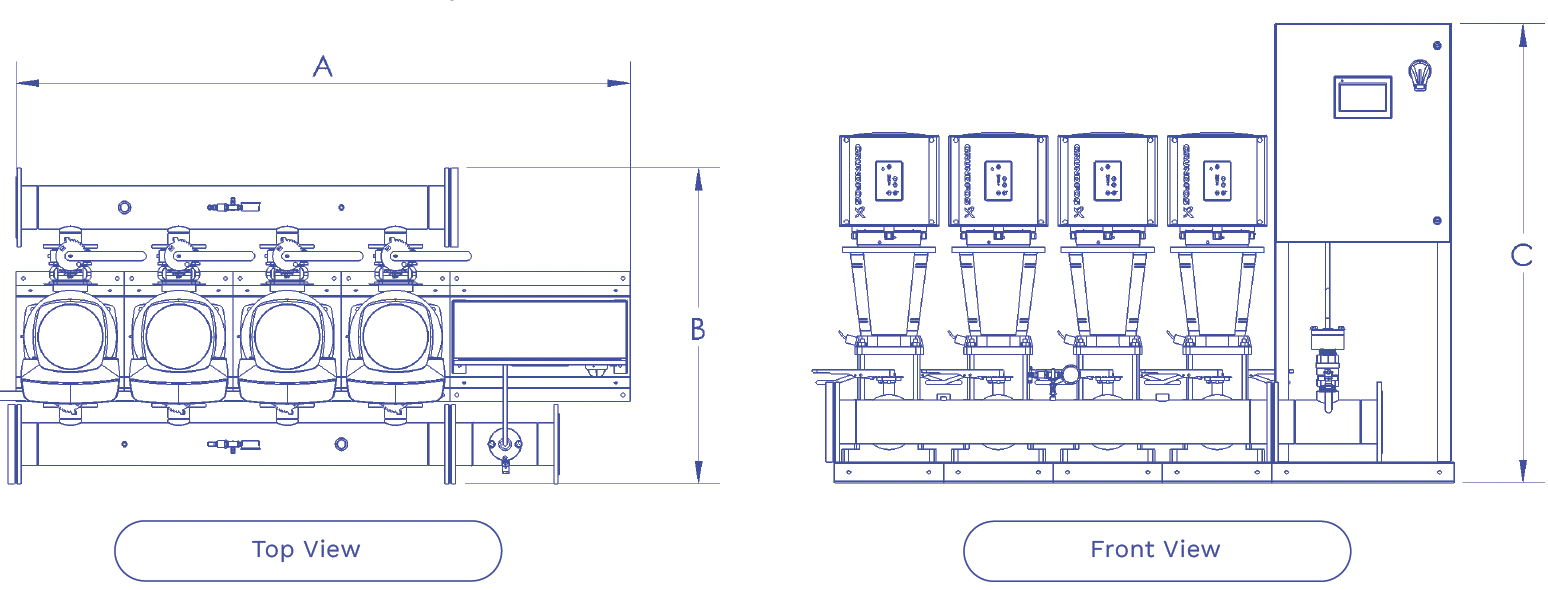

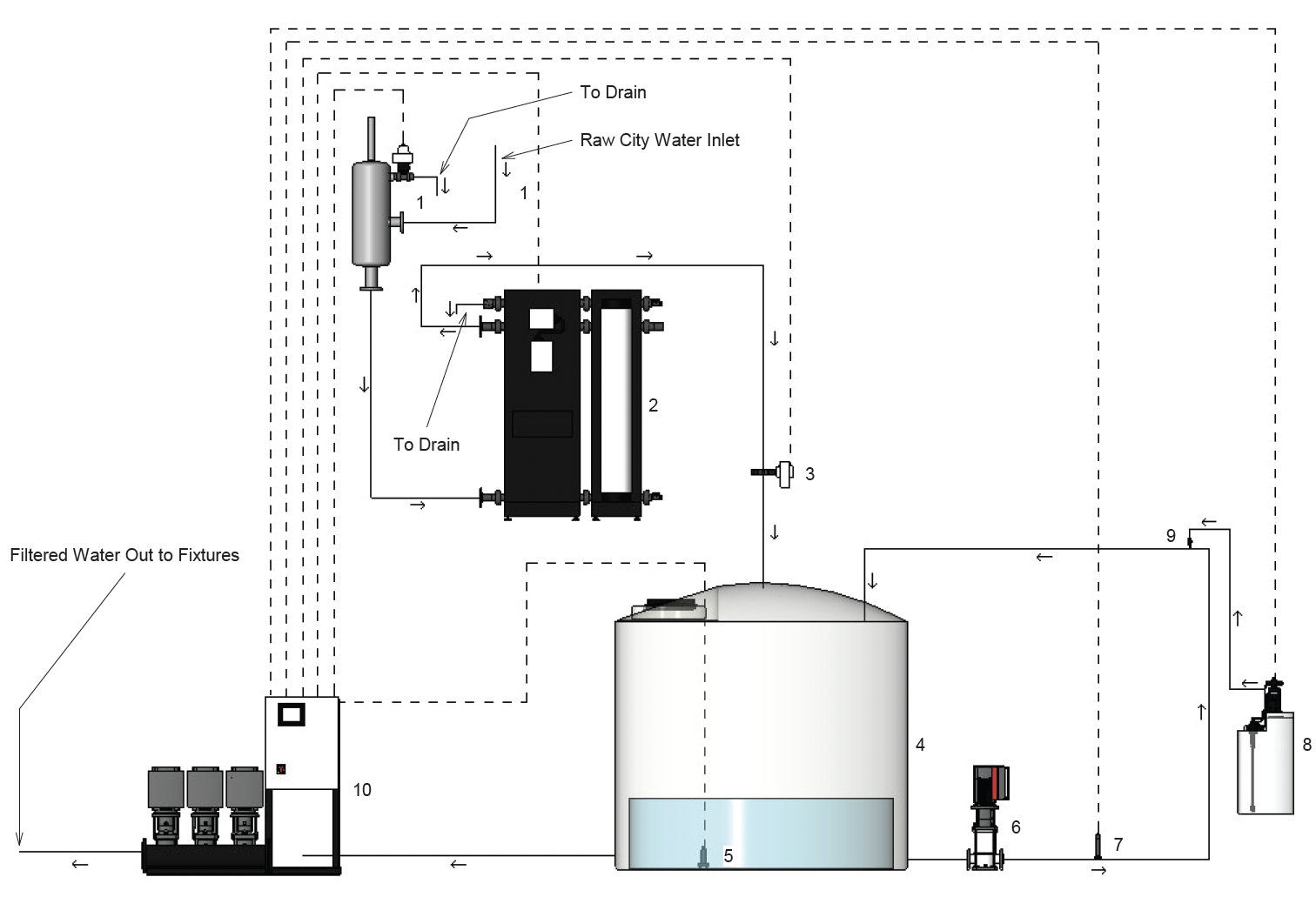

Intelligent Pressure Booster Systems

Applications

-

+