Major Hospital with Level I Trauma Center

Equipment Description:

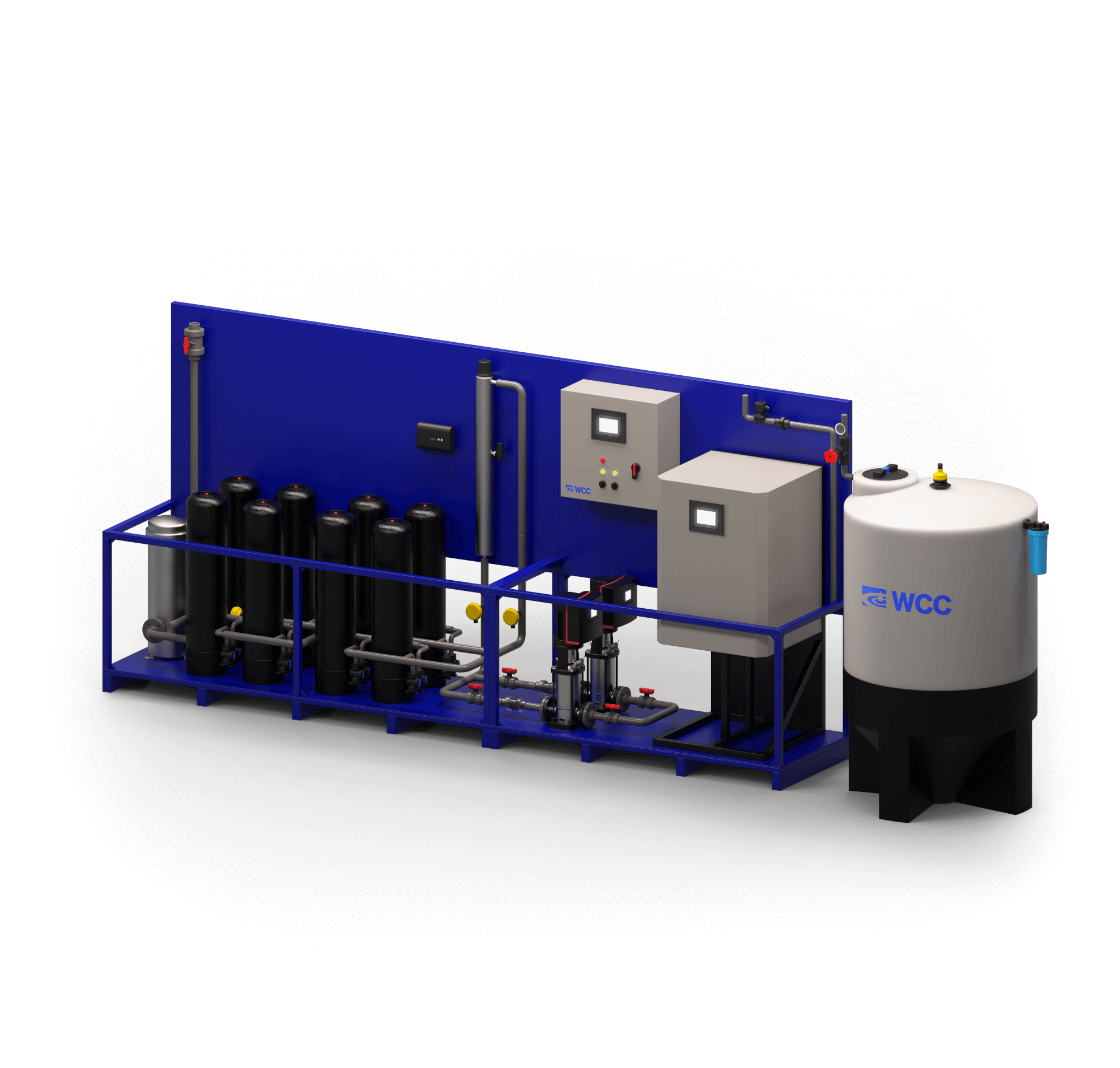

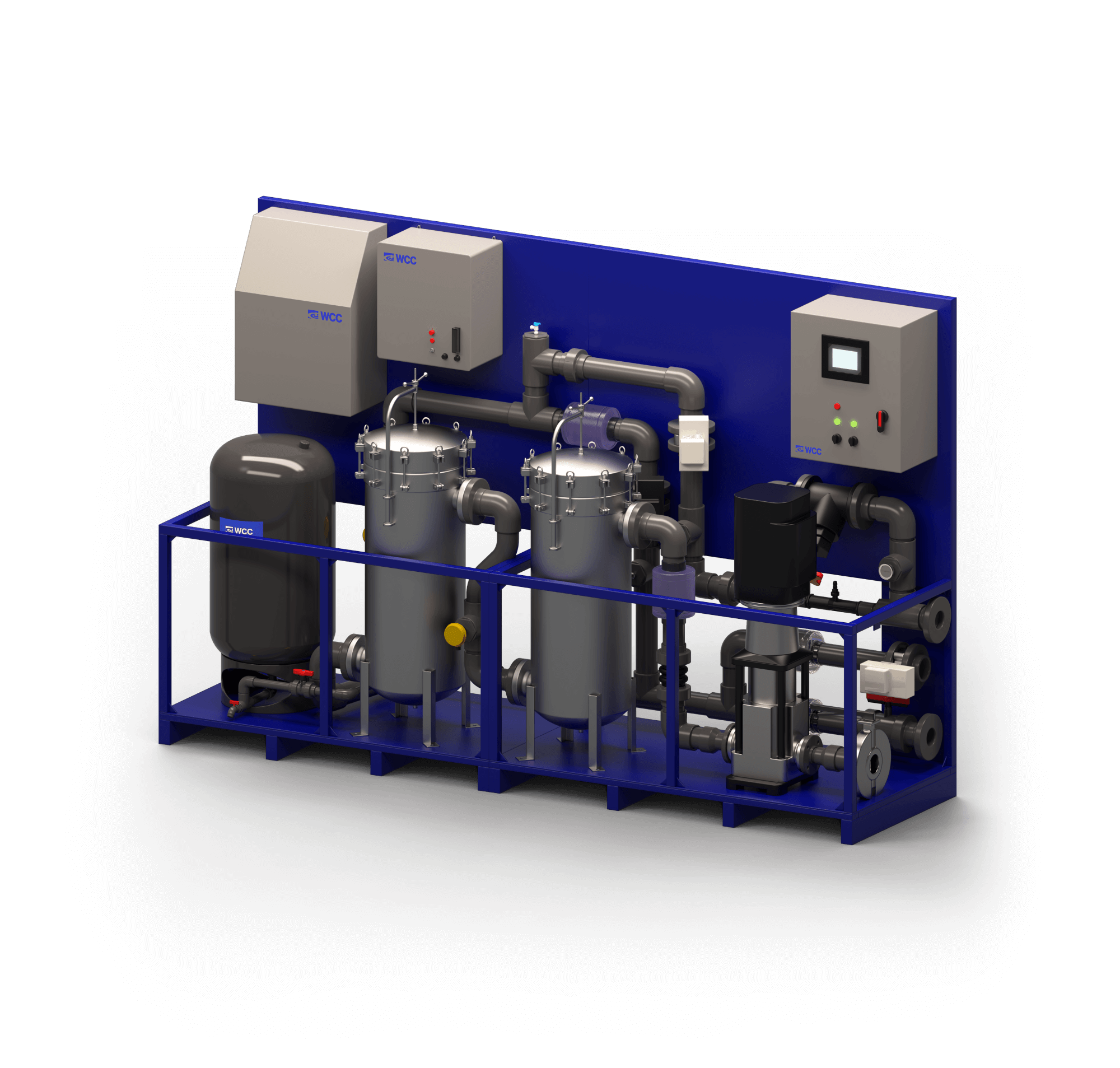

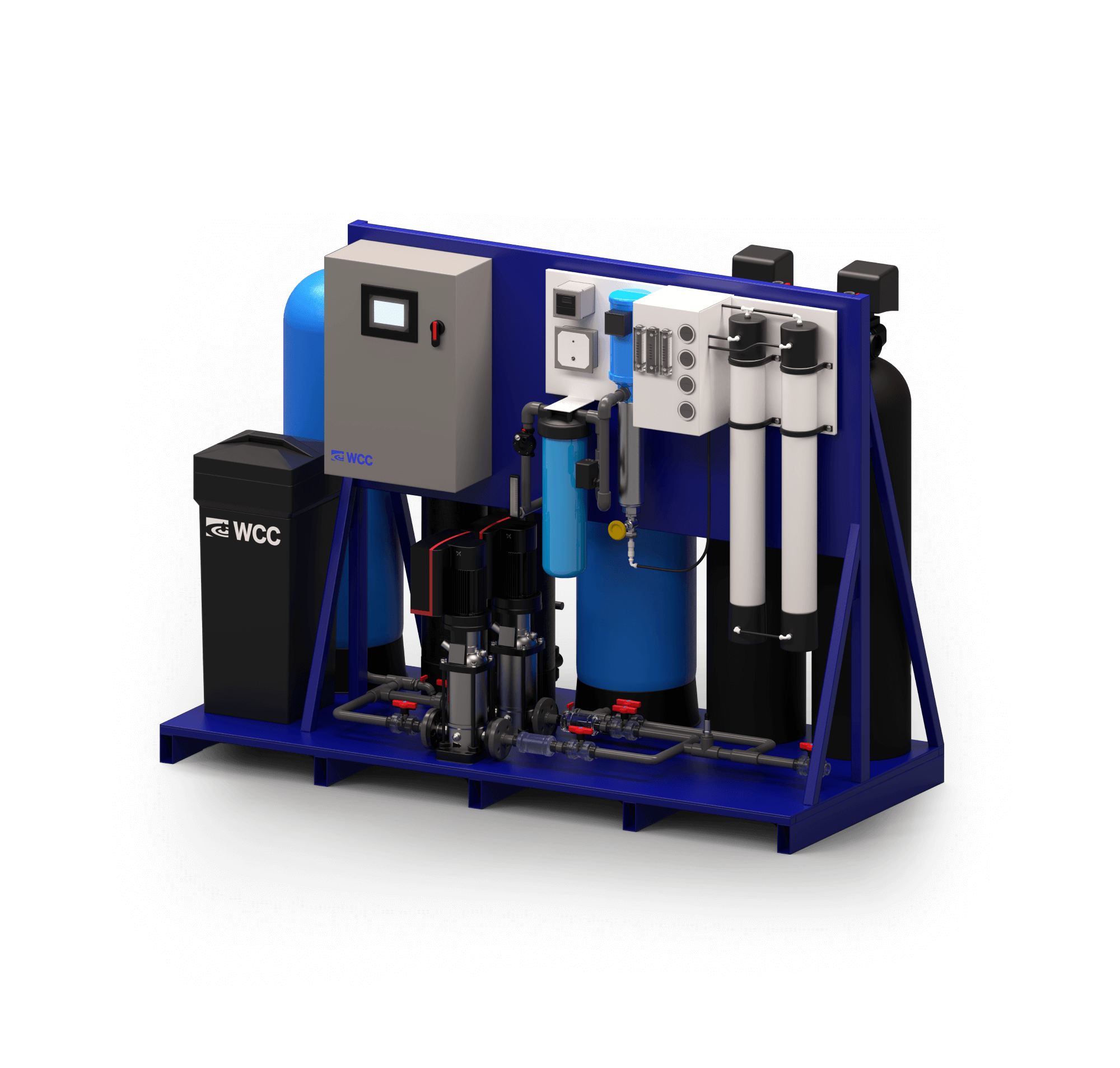

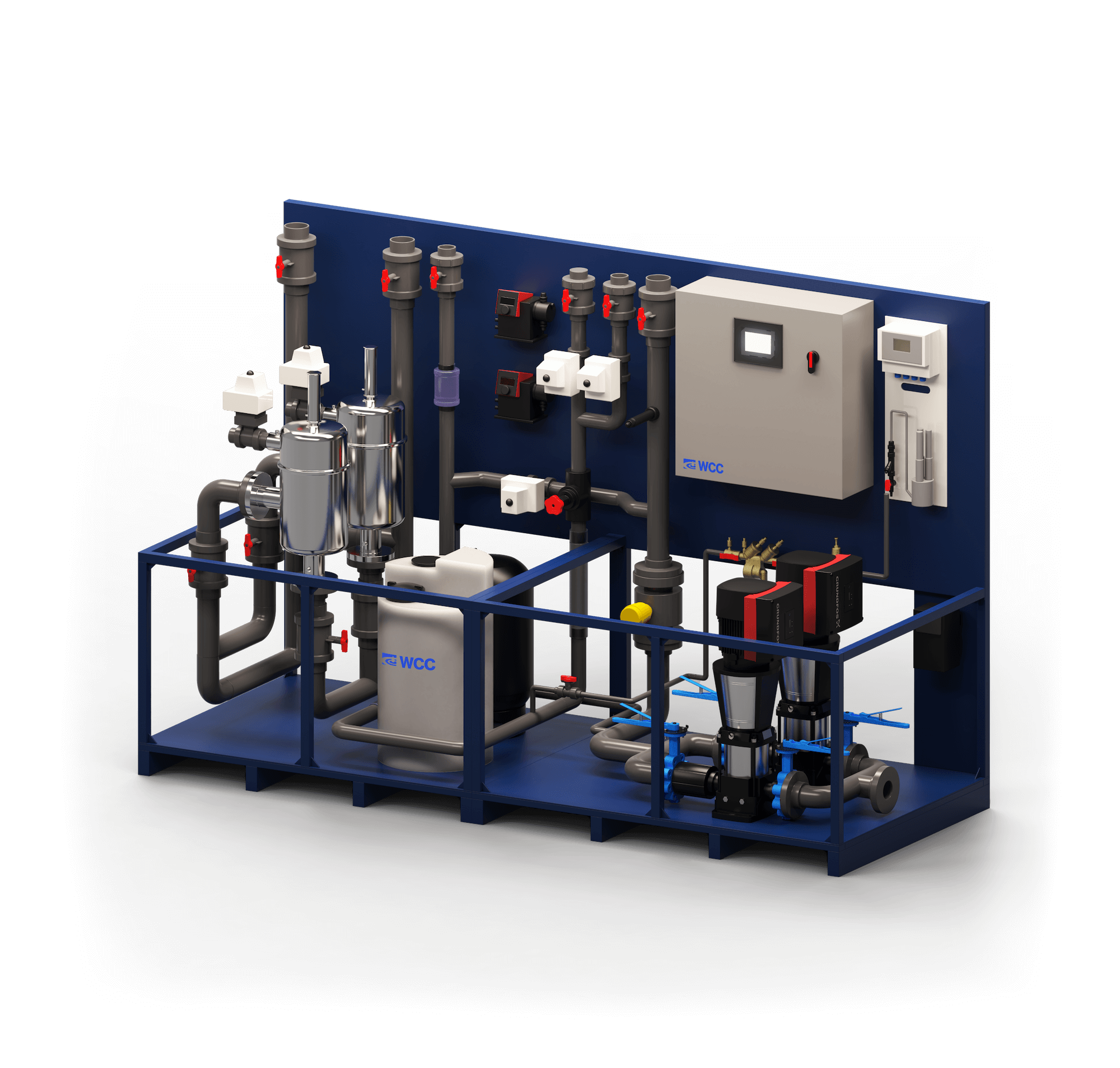

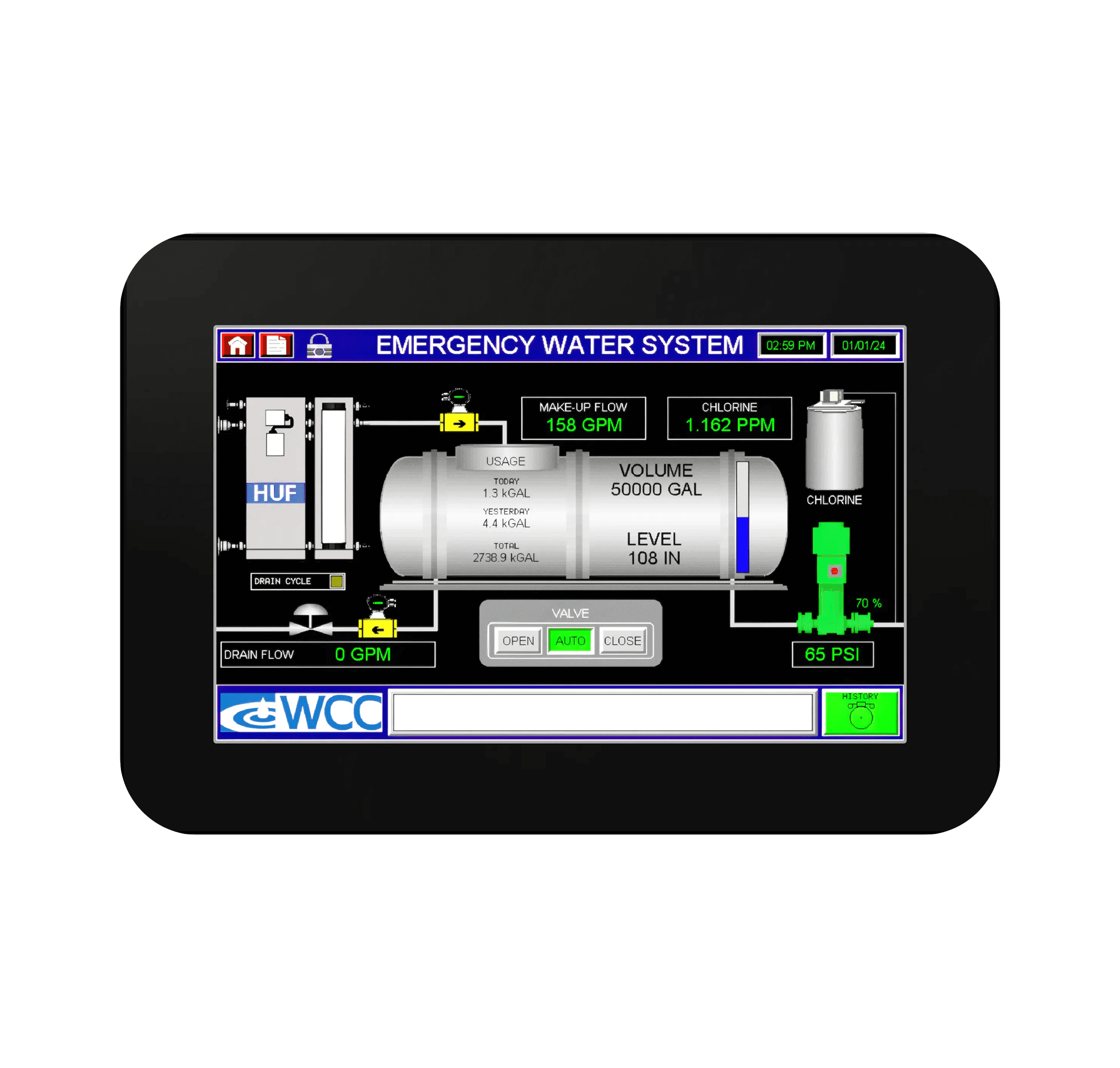

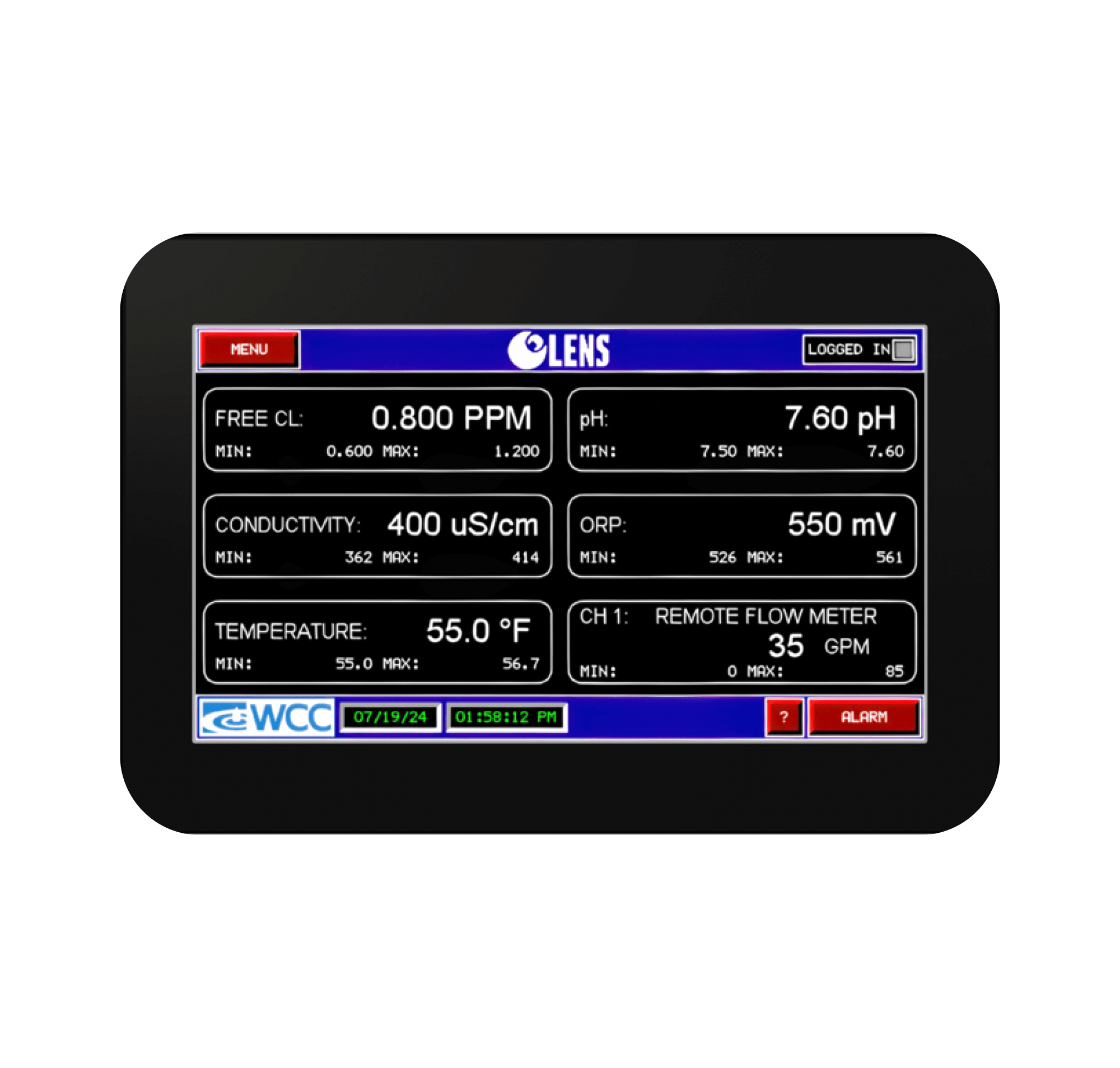

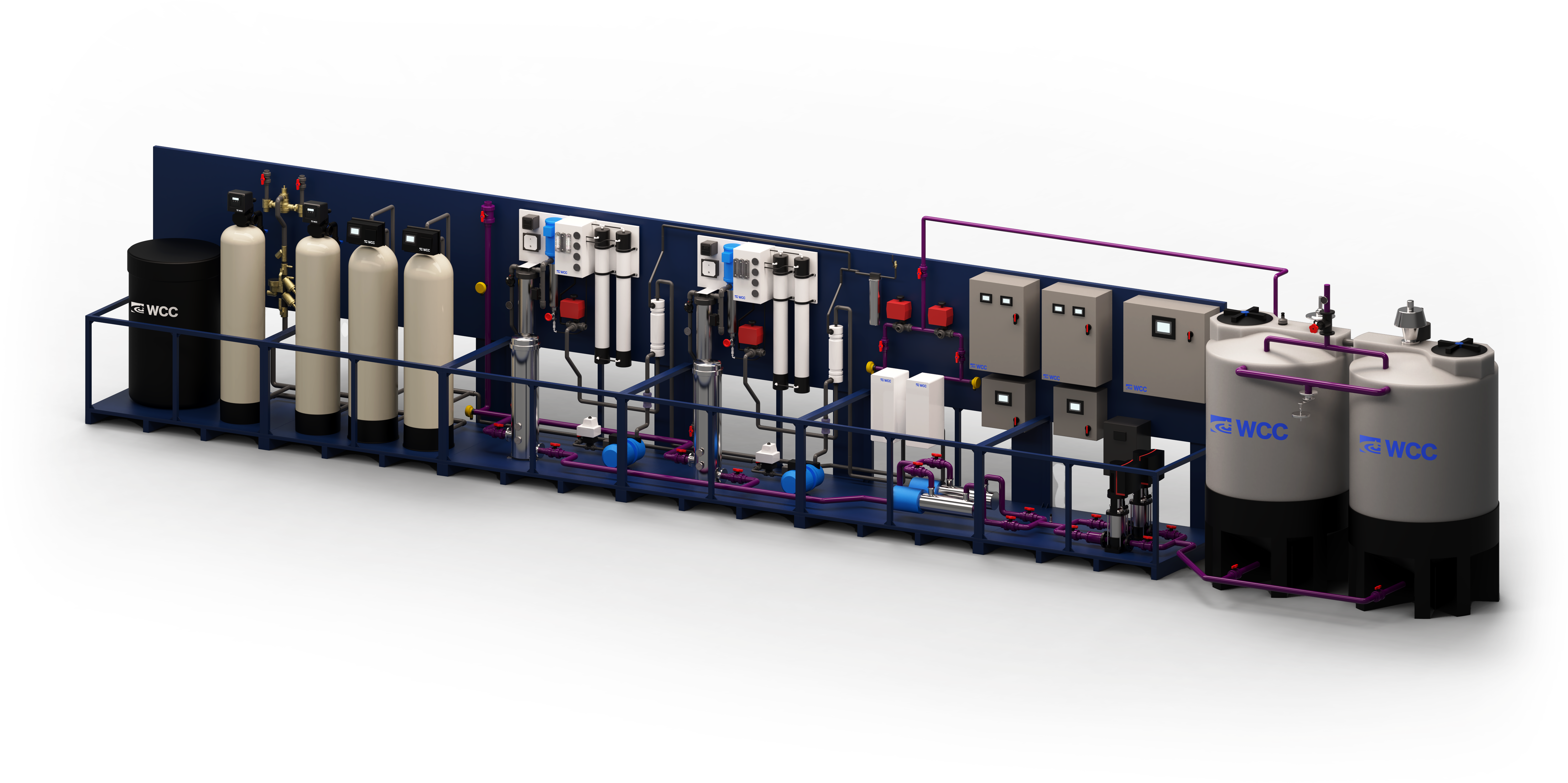

A pre-piped, pre-wired, skid-mounted system with all the pre-treatment, production, degasification, polishing, disinfection, storage and delivery equipment necessary for CLSI GP40 Clinical Laboratory Reagent Water (CLRW). 100% redundancy on all key components.

Problem:

The largest hospital in a major US city required an upgrade to the water supplied to its medical test labs. The existing central system did not generate purified water in compliance with current CLSI standards, particularly when it came to bacteria and endotoxin levels. As such, the facility was forced for several years to use expensive/cumbersome point-of-use microfilters. Because this was a Level I Trauma Center, any new solutions needed to include 100% redundancy for all critical equipment and state-of-the-art controls, capable of seamless integration with building automation systems.

Solution:

Working with the licensed MEP firm assigned to the project, WCC developed a complete package including mixing valves, triplex water softeners, triplex carbon filters, pre-filters, twin reverse osmosis (RO) systems, degasification membranes with onboard vacuum pumps, twin electrodeionization (EDI) systems, nitrogen-blanketed storage vessels with controls, twin 20 GPM delivery pumps with integral VFD’s, polishing filters, UV disinfection units, endotoxin filters, and advanced PLC controls. Everything was pre-plumbed, pre-wired, and pre-tested. WCC’s technicians and local representatives provided consultation and training to all parties involved and remain available at any time for troubleshooting, service, and support. Currently the hospital enjoys a steady supply of 10+ megohm CLRW-grade water, free from concerns of bacteria and endotoxin contamination.